On a sunny day in July, we met Max and Lenni, the inventors of Timberjane®, at the Motion Lab, a prototype workshop in Berlin. We talked about their journey to founding the company, the challenges they faced and the exciting developments of their innovative growbox.

Please introduce yourselves and tell us what you did before Timberjane®.

Lenny: Hello, I’m Lenni. I founded our company together with Max in 2018. Before that, I studied industrial engineering and got a taste of working for one or two large companies. But in the end, self-employment appealed to me and by happy coincidence I came to this project with Max.

Max: Hello, I’m Max. I did a master’s degree in geotechnology, but quickly realized that oil exploration wasn’t for me. I was interested in living plants, so I studied horticultural phytotechnology. I wrote my bachelor’s thesis about our growbox. Lenni and I found each other and have been working on our shared dream ever since.

What is the Timberjane®? Why should I buy one?

Lenni:

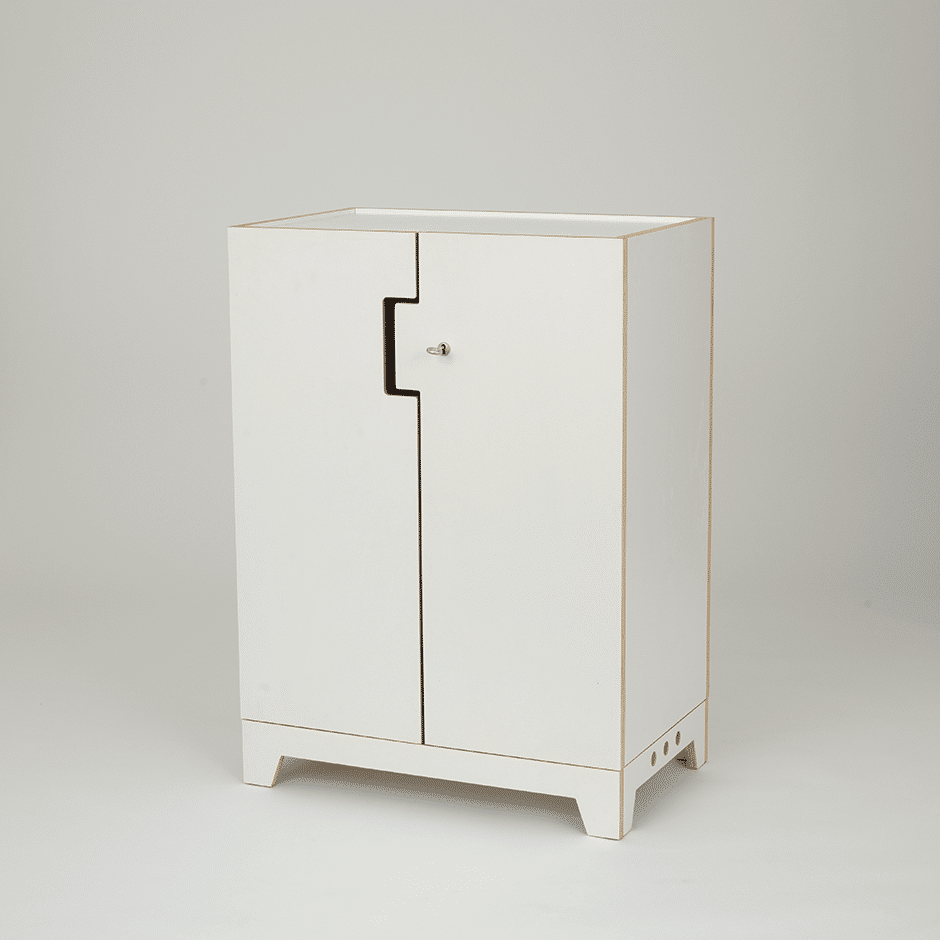

The Timberjane® is a fully automatic way of growing plants in a stylish piece of furniture. It is a wooden cabinet that integrates perfectly into your living environment. It is odor-proof, quiet and extremely efficient and takes care of all the steps from germination to harvesting and drying. The app keeps you constantly informed about what’s happening inside. Why should you buy the box? Growing is fun when everything works, but beginners are often overwhelmed. What equipment do I need? Which fertilizers? How do I put everything together? When do I need to water? Etc. We have been asked many questions over the years and have also conducted our own surveys. The answer to all these questions is now our Timberjane – laughs. If you value an aesthetic living environment and want to go on vacation for two weeks without having to worry about your plants, we have the solution.

Max: It is also worth noting that the furniture is only about one meter high. Many people fear that the plant will grow through the ceiling or that the yield will be too low. Our control system prevents this, and our side-mounted lamps enable 30% more yield from the same area. This means we get about one gram per day, roughly 70 grams every 70 days – that’s more than solid for an area of 0.2 square meters.

You spontaneously moved the interview to the Motion Lab Berlin, why?

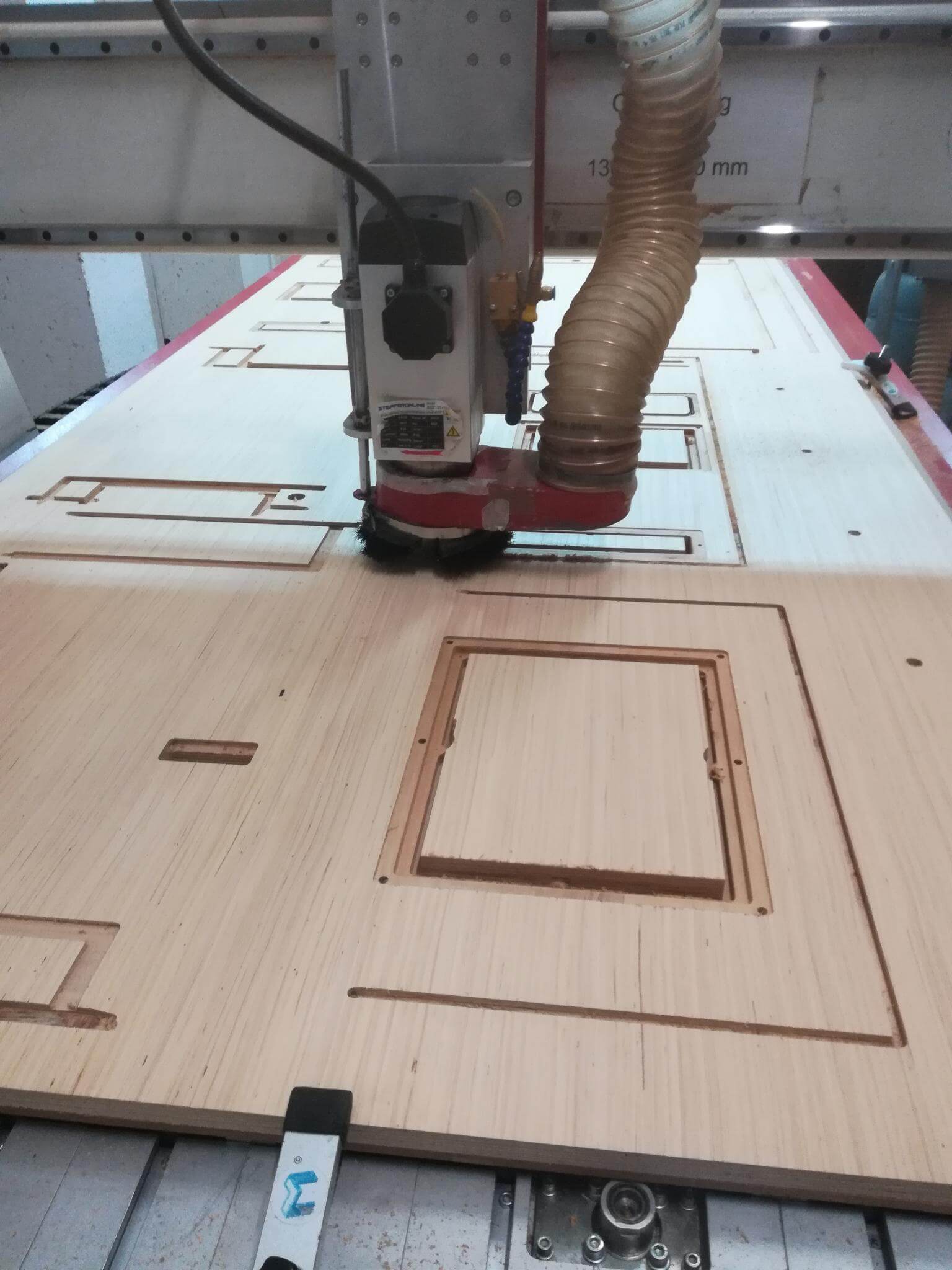

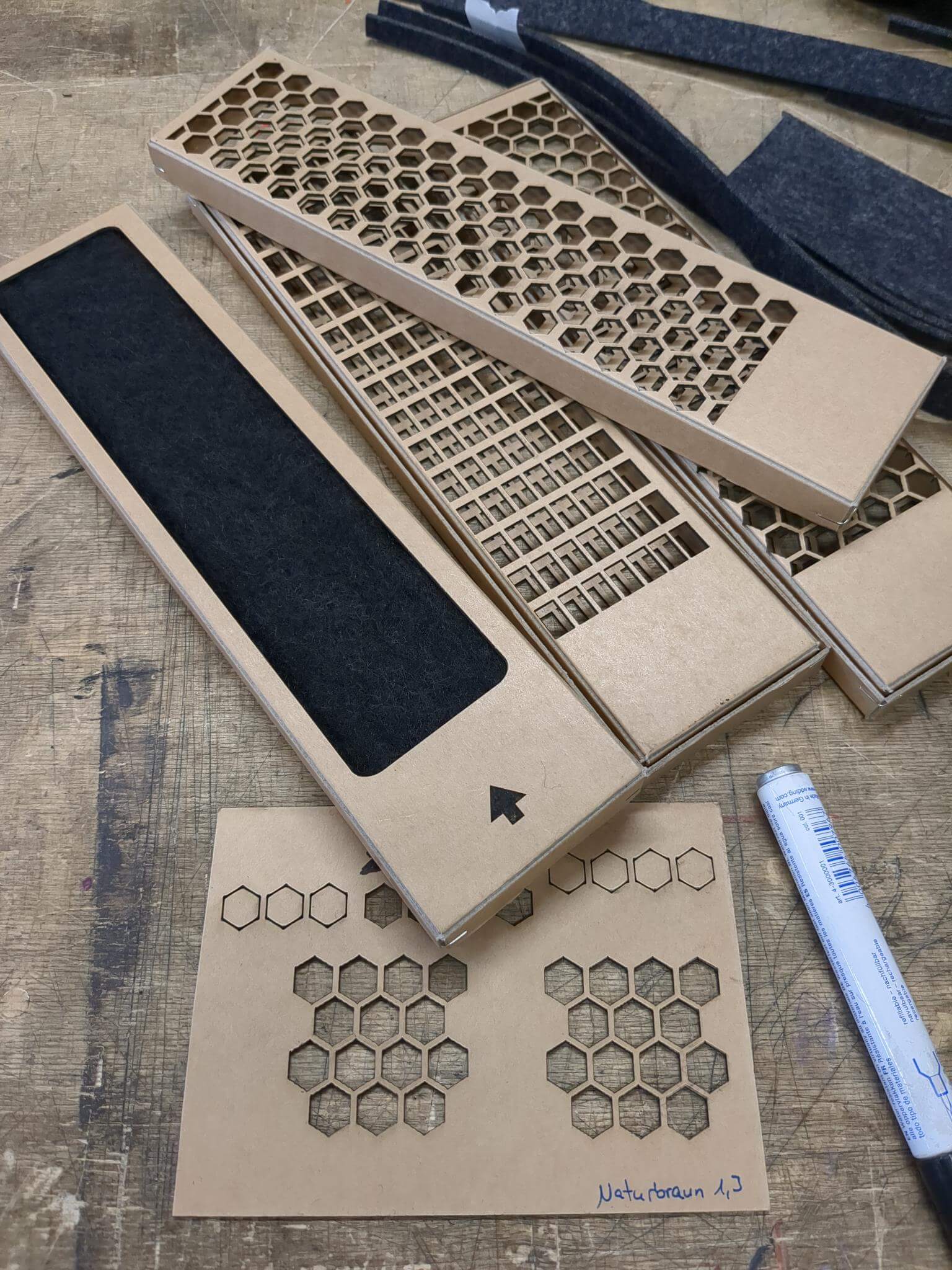

Lenni: We have a great infrastructure here to manufacture prototypes and produce series. Today, we have to use the machines and still have laser cutting and 3D printing ahead of us. We are also part of a large community here, all with their own exciting projects.

How long did the development take? Where were the biggest blockages/time wasters?

Lenni: To be honest, we’re not 100% finished yet. We are at 95 to 98 %, depending on which part you look at. The development was extremely exciting, but also lengthy, as our aim was to harmonize all the components and adapt everything to the cannabis plant. For example, to design the piece of furniture so that it is odor-proof without using rubber seals. It must also meet the requirements for warping due to humidity and temperature differences. These processes cause tension in the wood, which we had to withstand in terms of design and also here with the restriction of only using saliva-proof lacquers and oils. That was a major part.

Max: There were an incredible number of challenges. There were three of us at the start, then one of us didn’t want to carry on. How do you deal with that? Then our IT guy dropped out and we had to deal with that too. With few financial resources, we had to solve problems cleverly without spending a lot of money. There was some bad news that we had to get over in order to continue developing. Every component presented a new challenge. The furniture, the lamps, the filters, ventilation systems, surface treatment, hinges, screws, the app, the data infrastructure and all the business stuff. It’s a constant challenge.

How are the roles in the team distributed, especially with regard to team leadership and project management?

Lenni: We don’t have a strict distribution of roles, but we both have our strengths. Apart from Max and me, there are other people involved. We are both managing directors. I take care of the financial plan and legal matters and am good at 3D modeling. That helps us with the production of the furniture and other components.

Max: I am responsible for connecting plants and technology. In some areas we have a clear division, in others whoever has capacity steps in. We have two other employees, a father-son duo, who are responsible for hardware and software development. Fortunately for us, these two also believe in our project, as our personnel costs for the two top employees would otherwise be immensely high. The fact that they invest so much motivation and time in the project is the reason why we still exist today.

How did you come up with the name Timberjane® and have you taken measures to protect the name legally?

Lenni: Timberjane® came about after a long process of searching for a name. The idea came to us on a trip to the Uckermark. Timber stands for wood and Jane for Mary Jane. We liked the name and registered it. First in Germany, then in the EU, Great Britain and Switzerland. So we have the prospect of selling our product under the brand in the main European countries.

How expensive is it to protect a name in Germany and the EU?

Lenni: In Germany, we paid around €900, and almost as much again for the EU trademark application. There are great grants where you get 50% of the costs reimbursed. For Switzerland and the UK together, it was around €300 to €400.

Why did you decide directly to set up a GmbH and not a GbR or another legal form?

Max: We actually founded a GbR first in 2018, on Maundy Thursday – appropriately enough.

Lenni : The GbR was an easy way for us to get started, as it is unproblematic from a tax perspective. With the GbR, we were able to apply for funding and appear more reputable to companies and manufacturers. We founded the GmbH in May 2023 when we went public and developed the first product parts. From a tax perspective, it would have been complicated to transfer everything from one company to the other. My father is our tax advisor, which made the process easier. We applied for the start-up bonus, which would no longer have been possible with the old GbR. The GbR still exists and holds trademark and patent rights so that we don’t have to cede them to potential investors.

How did you raise the start-up capital for your company? Did you take advantage of any grants or other subsidies?

Lenni: It depends on what stage you are at. In Berlin, the universities are great at answering bureaucratic funding questions. Even if the cannabis issue is rarely well received. We found contacts at various start-up fairs. The IBB (Investitionsbank Berlin) is a good point of contact and offers seminars and workshops on funding. We tried a lot, didn’t get a lot, but the potential was seen. We primarily financed ourselves and worked a lot. Many friends helped us free of charge or at low cost.

Receive up to €17,500 from the state now!

We at 420MKT are also eligible for subsidies and can have our services subsidized by up to 80% through BAFA and godigital. Contact us for a non-binding consultation.

Did you have to draw up a detailed business plan for the financing? If so, how did you go about it?

Lenni: We have written various business plans, always tailored to the respective funding program. I would always recommend creating one to uncover any ambiguities. You should be able to answer the core questions of your business yourself, otherwise you are heading in the wrong direction.

What advertising measures do you think are most important to successfully market your grow box?

Max: We are currently relying on word of mouth and trade fairs, as we have a high-priced product. Trust is important, and you gain this through recommendations and direct contact at trade fairs. We want to grow organically and don’t want to launch any major marketing campaigns until we can deliver in large quantities. In the long term, we are relying on influencer marketing and the advertising channels of our business partners.

What challenges have you experienced when renting commercial space and how did you deal with them?

Lenni: None so far. Fortunately, we have a lot of friends, so we already have several affordable options in Berlin and Brandenburg if we want to expand our production space.

Where do you source the raw materials for your grow boxes? Do you work with certain retail chains or suppliers?

Lenni: The piece of furniture is made of birch wood with real wood veneer from sustainable sources, manufactured in Germany. The electronics are manufactured in Europe, the lamps partly in Turkey. We aim to produce everything at European level. Some of our prototypes came from China, but we now have European partners for series production.

To what extent does sustainability play a role in your company and in the production of your grow boxes?

Lenni : Sustainability was important right from the start and it took us a lot of time. We reduce plastic to a minimum, use plant-based felt for seals and rely on wood, which stores CO2 and has a better balance sheet than plastics and metals.

Max: Our boxes are also extremely energy-efficient, with electricity costs of around €7 per month. What’s more, we’ve designed everything so that it’s all modular and replaceable – the anti-IPhone principle, you could say. Even after technical updates, parts can be easily replaced. Our designs are built to last, at least five years.

How do you rate the competition in the grow box market? Are there certain competitors that you particularly respect or that challenge you?

Max: There are other interesting solutions on the market, all with their own strengths and weaknesses. However, I have yet to see the level of automation and aesthetics of our product anywhere in the world. Our boxes are small, efficient and beautifully designed.

Do you have any tips for founders and people who are on a similar path?

Max: Uses AI to structure work processes and work faster. There are many helpful tools that can save you a lot of time and work.

Lenni: Talk to people who are more familiar with a topic. Get advice and benefit from the experience of others. Networks like the Motion Lab can be extremely helpful.

Do you have any final words, concerns or tips?

Max: If someone with a nice internet presence and a certain number of followers is interested in testing our product, we would be happy to receive inquiries and cooperation partners.

We will stay in touch with the guys and follow the further development of the Timberjane®. For more information and contact options, go to www.timberjane.com.